Ideal Fibre Industries Limited is one of the leading flexible packaging company in Bangladesh. We supply quality products of printed flexible packaging material using fully automated rotogravure printing technologies for various form of laminates with foil, film & paper. All kinds of flexible packaging materials using advanced technology machinery and fully automated Rotogravure technology to fulfill the needs of the local market. Our professionals offer one stop service .cost effective and innovation packaging solutions. We take pride in providing quality product along with unparalleled customer service.

Through the overview of 4 layer film making machine, Lamination extrusion machine, 8 color printing machine and a state of the art Quality Control Lab Premiaflex Plastics has been able to manufacture high barrier edible oil and dairy based products, provide 5 layer packaging with spot lamination and provide the highest quality of packaging. We have been able to ensure the best quality inspected products for our customers.

We specialized in rotogravure printing and lamination of various high quality plastic packaging materials including PET, BOPP, MPET, MCPP, Aluminum Foil ,Shrink film, Pearl film, LLDPE, etc. Our products can be presented in roll, bag, or sleeves form.

Product Description:

Machinery and equipment selected for this project to manufacture various types of Flexible printing & packaging items as listed below:

- 2 Layer wrapper – PET+LLDPE

- 2 Layer wrapper – PET+ MCPP

- 2 Layer wrapper – BOPP+MCPP

- 2 Layer wrapper –MAT BOPP+MCPP

- 3 Layer wrapper – PET+MPET+LLDPE

- 4 Layer wrapper – PET+PE+MPET/Alu Foil+LLDPE

- Paper Back Alu Foil – Paper+ ALU Foil

Features:

- Excellent machine ability with good seal strength

- Excellent aesthetics

- High whiteness index

- Very good print ability

- Good optics

- Good stiffness

- Good barrier to normal and UV Light

- High haze for natural look

- Good ink adhesion on glossy side

- Good contact clarity

- Good moisture barrier

- Low static charge

- High heat seal strength

- Good optical properties

- High yield

- Printable surface with sparkling gloss

- Surface suitable for fusion with PP container

- Good anti static

- Suitable for Offset, Rotogravure & Flexo graphy printing.

- Seals at low temperature, hence broader heat seal temperature range

- Low COF throughout printing & laminating process

Wide Range of Industrial Applications:

- General purpose printing and pouching of snacks and bakery products

- As a component in multi-layer laminate for VFFS & HFFS application

- Reverse printing & lamination for natural / matte looks

- Strip packaging for cough drops

- In-mold labels for PP & PE Injection molding

- Packaging of fresh cut vegetables, salad and meat, flower wrapping

- General purpose printing and pouching of snacks and bakery products

- Used as a reverse printed top layer in laminates of multi layer-web

- Roll Fed Wrap Around Transparent or ‘No Look’ Labels

Production Capacity:

| Sl. | Name of Product | Unit | Qty/Month |

|---|---|---|---|

| 1 | 2 Layer wrapper for Rice, Atta, Detergents | MT | 250 MT. |

| 2 | 3 Layer wrapper for Spice, Crackers ,Milk Powder | MT | 300 MT. |

| 3 | 4 layer wrapper for Chips, Chanachur, medicine | MT | 300 MT. |

| 4 | PVC shrink Lebel for Water, Juice, Liquid Soap | MT | 50 MT. |

| 5 | Blister Foil for Pharmaceuticals | MT | 50 MT. |

| 6 | Paper back Alu foil for Tobaco | MT | 50 MT. |

| TOTAL | MT | 50 MT. |

Above listed packaging items to be used for packing of dry as well liquid formed materials mainly Rice, Atta, Flour, Suji, Sugar, Milk (powder and liquid), Tea, Biscuit, Bread, Chanachur, Chips, chocolate, mineral and drinking water, edible oil, baby food items, tissue paper and pampers, soap, various detergent products, cosmetics, seeds, pharmaceuticals, chemicals, and other so many items.

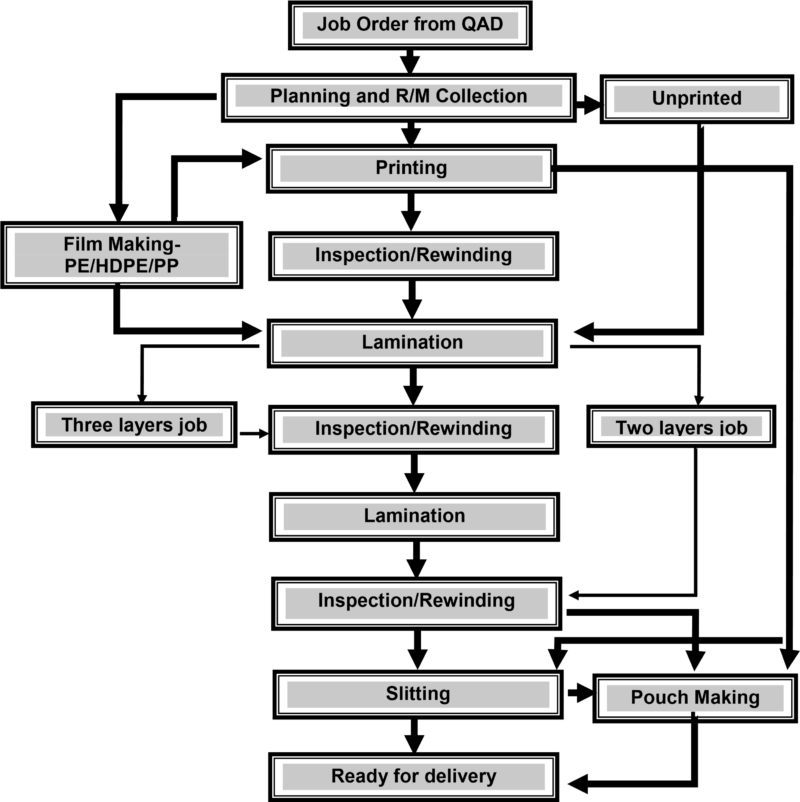

Manufacturing Process: